Why Strong Door Locks Are Essential for Trailer Security

Cargo theft is on the rise, with organized crime targeting unattended trailers, parking lots, and distribution hubs. A trailer door is the last line of defense between your shipment and a potential loss. A weak lock invites forced entry, costing fleets not only the value of stolen goods but also insurance hikes, missed deliveries, and damaged customer trust.

A strong trailer door lock does more than deter. It delays and resists physical attacks, giving thieves fewer opportunities and law enforcement more time to respond. For decades, Transport Security’s ENFORCER® line has set the standard in heavy-duty protection for trailers, containers, and trucks.

Types of Trailer Door Locks

Not all locks serve the same purpose. Each type offers a unique layer of defense, and often the best protection comes from combining them.

- Trailer Padlocks

Heavy-duty padlocks secure the hasp, latch, or handle on swing and roll-up doors. A high-security padlock should feature a shrouded shackle to resist bolt cutters, case-hardened steel construction to withstand saws and grinders, and a pick-resistant cylinder for advanced key control.

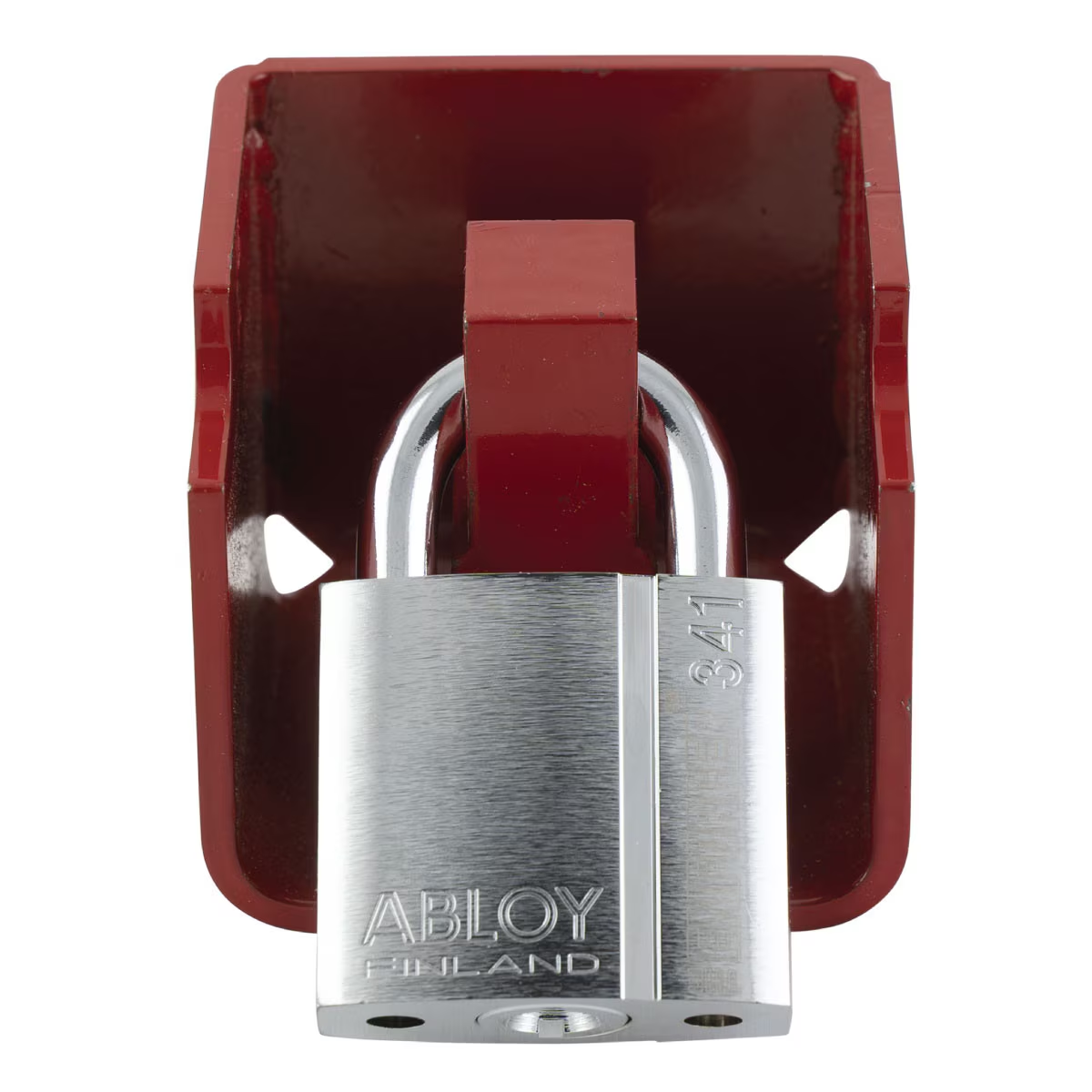

Example:

The ENFORCER® ABLOY® 341 Series Padlock provides unmatched resistance to cutting and prying. Built from case-hardened boron steel, it’s ideal for trailer doors and containers. When paired with a compatible ENFORCER® hasp, it forms a complete locking system tested under extreme conditions.

- Hasp Locks

Hasps act as the anchor point for your padlock. A high-quality hasp should have minimal exposed hardware, tamper-proof installation, and a design that prevents pry bar attacks.

Example:

The ENFORCER® Hasp is built from 10-gauge high-strength steel and available in multiple models to fit dry van or reefer swing doors. Its welded housing shields the padlock shackle, creating a seamless defense against tampering. Many leading fleets trust the ENFORCER® Hasp as part of their standard security package.

- Adjustable Trailer Door Locks

Adjustable locks provide versatile protection for trailers that may not use permanent hasps. Instead of securing a single latch point, these locks wrap around both locking rods on the trailer doors, preventing them from opening. They are a preferred choice for fleets needing a universal, portable solution that fits multiple trailer types or leased units.

Example:

The ENFORCER® Adjustable Trailer Door Lock is constructed of chrome plated steel and adjusts to fit the locking rods on both swing door trailers and shipping containers. Once positioned, it secures in place with an ABLOY® high-security padlock, creating a solid barrier against forced entry and tampering. The adjustable design allows it to be shared across trailers of different widths, making it a practical investment for fleets and owner-operators alike.

This style of lock delivers visible, physical deterrence and eliminates vulnerabilities where thieves might otherwise pry or cut through the latch. It is simple to install, weather-resistant, and proven to perform in demanding over-the-road environments.

- Seal Guards

A seal guard protects your trailer’s tamper-evident seal from being removed or replaced without detection.

Example:

The ENFORCER® Seal Guard Lock combines a physical seal barrier with an ABLOY® cylinder lock, offering visual verification that the seal remains intact. It’s especially effective for high-value or high-integrity cargo such as pharmaceuticals and beverages.

The Importance of High-Quality Materials

When selecting a trailer lock, material quality directly impacts performance. Cheap zinc or mild-steel locks might look solid, but they’re easily breached by hand tools. High-value fleets rely on case-hardened steel or boron-reinforced components for superior cut and drill resistance.

Over time, investing in better materials saves money by reducing replacements, insurance claims, and downtime.

Weather-Resistant Designs for Long-Term Reliability

Locks are exposed to rain, salt, dust, and extreme temperatures every day. Without weather protection, corrosion can weaken internal components and make keys difficult to turn.

ENFORCER® and ABLOY® locks are extensively tested in harsh environments, from Minnesota winters to Gulf Coast humidity, to ensure consistent operation year-round.

The ABLOY® Advantage: Pick Resistance and Key Control

Key control is one of the most overlooked aspects of trailer security. A strong lock means little if unauthorized copies of the key are circulating.

ABLOY® cylinders, used across the ENFORCER® line, provide patented key systems that prevent unauthorized duplication. Each key is tracked and can only be reproduced with proper authorization, which is critical for fleets managing multiple drivers or locations.

ABLOY®’s rotating disc cylinder design also offers exceptional pick and drill resistance. Unlike conventional pin tumblers, these cylinders have no springs to wear out, giving them one of the highest resistance ratings in the industry.

Manual vs. Auto-Locking Mechanisms

Choosing between manual and automatic locking systems depends on your security needs and workflow.

Manual Locks (such as traditional padlocks and hasps) require physical engagement, giving the user control over when and how the lock is applied. They’re reliable, simple, and easy to maintain.

Auto-Locking Systems engage automatically when doors close, reducing human error and ensuring security even if a driver forgets to lock up.

For most fleets, manual systems like ENFORCER® hasps and ABLOY® padlocks remain the preferred choice due to their proven mechanical reliability and straightforward operation.

Key Factors to Consider When Choosing a Trailer Door Lock

Ease of Use

Drivers need a lock that can be applied quickly without complicated alignment or special tools. A cumbersome lock slows down operations and risks being skipped during tight schedules.

Durability

Frequent exposure to vibration, moisture, and impact demands a lock that won’t seize up or fail over time. Look for weatherproof materials, corrosion-resistant finishes, and tamper-proof hardware.

How the Right Lock Prevents Theft and Saves Money

Cargo theft costs U.S. businesses hundreds of millions of dollars annually, often occurring in just minutes at unsecured stops. Beyond product loss, a single theft can ripple through supply chains, delaying deliveries, triggering penalties, and damaging client relationships.

By investing in ENFORCER® high-security locks, fleets prevent these losses before they happen. A $300 lock may seem costly until compared to a $200,000 cargo claim, higher insurance premiums, or lost contracts. Strong locks pay for themselves many times over in prevention, reliability, and peace of mind.

Conclusion

Trailer security begins with the door. The best lock isn’t just the strongest; it’s the one designed for your specific trailer type, cargo value, and operational needs. From hardened steel hasps and ABLOY® padlocks to specialized seal guards, Transport Security’s ENFORCER® line delivers a proven defense against theft and tampering.

Every lock you choose is an investment in uptime, compliance, and brand reputation. When your doors stay locked, your cargo and your customers stay protected.